Inlet transition to improve distribution across ESP’s, FGD’s & SCR

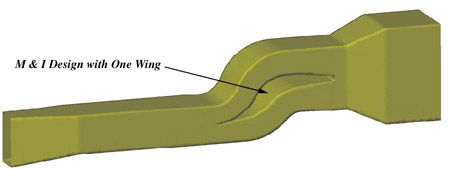

M & I Technology also offers significant benefits to improve flow across environmental components like ESP, SCR and FGD’s etc. This would result in improvement of environmental equipment performance and also reduction in pressure drop through the system. In many installations, environmental components have been poorly arranged due to space constraints, such that equipment suppliers have had to incorporate their own flow straightening devices into their designs (such as perforated plates, baffles, etc.) In some cases, additional surface or performance margins have been added to compensate for expected poor flow distribution across modules. This typically has resulted in non — optimized designs and higher auxiliary power consumption. M & I design approach is to improve flow patterns to all modules, thus increasing/restoring performance and reducing noise and vibration at its source. In many cases, the power robbing and inefficient baffles can be removed for even greater power savings and easier maintenance, etc.

Typical CFD simulation results are shown below:

- Horizontal duct and transition to HRSG for 75 MW power plant. M & I design offers 2″ W.G. reduction in pressure drop over existing inlet system with uniform flow across duct burners.

- Elbow ducts and transition to SCR downstream HRSG for 75 MW power plant. M & I design offers 25% reduction in duct length & layout and about 0.5″ W.G. reduction in pressure over conventional design.

M & I POWER TECHNOLOGY INC.

2140 Meadowpine Blvd, Mississauga, ON CANADA L5N 6H6

Tel: + / 905 – 812 – 3120

Fax: + / 905 – 812 – 3150

E-mail: [email protected]